The inspector and my contractor showed up yesterday and the setup breezed through inspection. Having a parallel PV installation was key here since it split out the existing residential/expense side of my electrical installation from the new commercial/revenue side.

As it turns out, electricians and even New Berlin electrical inspectors themselves have separate residential and commercial groups. Because our 1kW array is a revenue earning installation, the inspector was from the commercial side of the house and his task was simply to evaluate the PV portion of our dual meter installation. Had we gone with a serial PV setup (where the solar array is connected directly to a breaker on the main panel), then both groups would have been involved at all points of the project. In this scenario, the same tasks could have taken twice as long to accomplish due to the additional level of coordination required. Parallel installations are definitely the way to go!

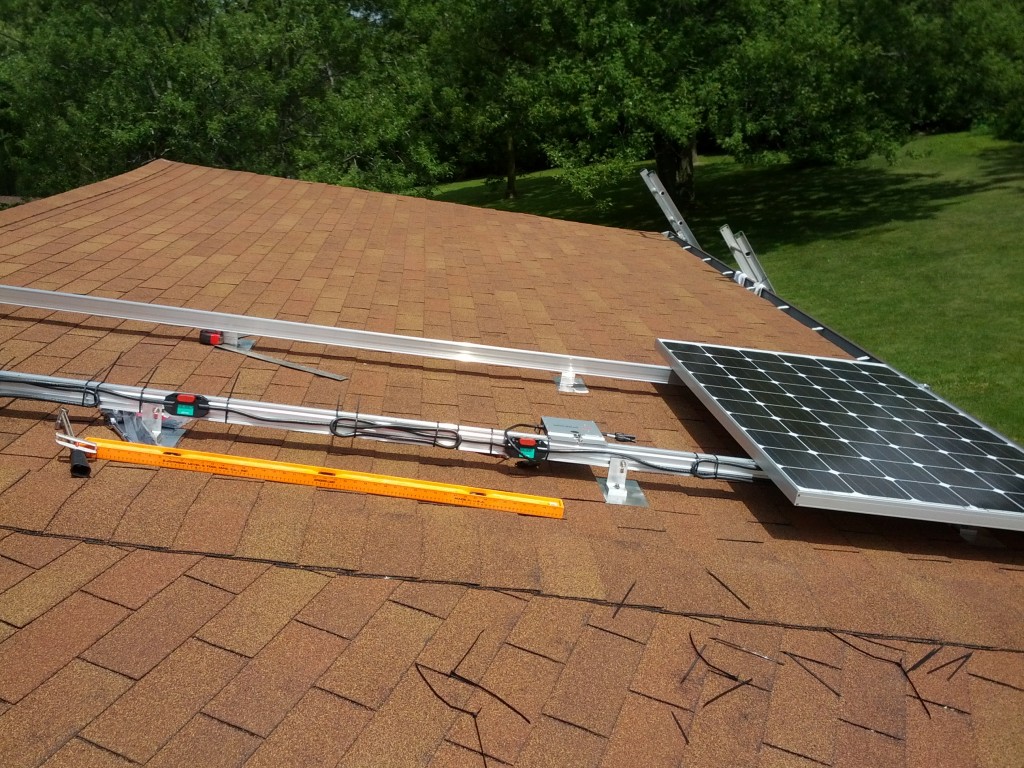

Our inspector was also quite impressed with the level of standardization on the roof. This was the first time he had inspected an Enphase M215 micro-inverter setup with engage trunk cable on standardized Renusol racking, and he quickly caught on to the implications. He even asked for cut sheets on the new inverter/racking technology for his personal records citing that this could “open the sluice gates” for home PV installations.

I couldn’t agree more.

So, what happens next?

- The inspector will inform our WE Energies contact person that the configuration is ready to commission.

- Somebody from WE Energies will be out before Friday to install the PV generation meter

- WE energies will show up on the afternoon of 9/13 to commission the system. Essentially, they will turn everything on at the disconnect, verify that it powers up correctly then (most important part), turn it back off to make sure the inverters shut down within 2 minutes. This test proves out the system’s the anti-islanding capabilities.

- Sometime in the future, a lineman will be out to replace the temporary splices at the service entrance weatherhead with their own. Interestingly, my contractor told me that it could be months before they got around to it. He also said to make sure they give back the current splices since they are apparently worth quite a few bucks on eBay…

On my immediate task list:

- Install a second TED5000 CT in the 6″ attic box and connect up to my TED5000 system. This circuit tap will measure PV output and allow my TED to precisely track overall PV system performance over time. I’ve ordered this component already and it should arrive sometime next week.

- Extend the computer room branch circuit up to the attic to provide connectivity to the TED CT. This will require BX armored cable and may be a bit of a pita since the cable itself will go up the chimney enclosure.

- Purchase 2 DIN mounted SPs to protect the array against lightning surges as well as a new Panel mounted SP to protect my extensive UPB installation.

- Fill out the Focus on Energy rebate form just as soon as I get the bill from my contractor. My deadline to accomplish this is October 10th.

These sit right on the top of the rail between the rail itself and whatever hardware is being mounted on it. When torqued to spec, four sharpened nubs on each end of the WEEB dig into the mounted hardware on one side and the rail on the other side. This forms a solid ground connection that is impervious to weather related corrosion.

These sit right on the top of the rail between the rail itself and whatever hardware is being mounted on it. When torqued to spec, four sharpened nubs on each end of the WEEB dig into the mounted hardware on one side and the rail on the other side. This forms a solid ground connection that is impervious to weather related corrosion.